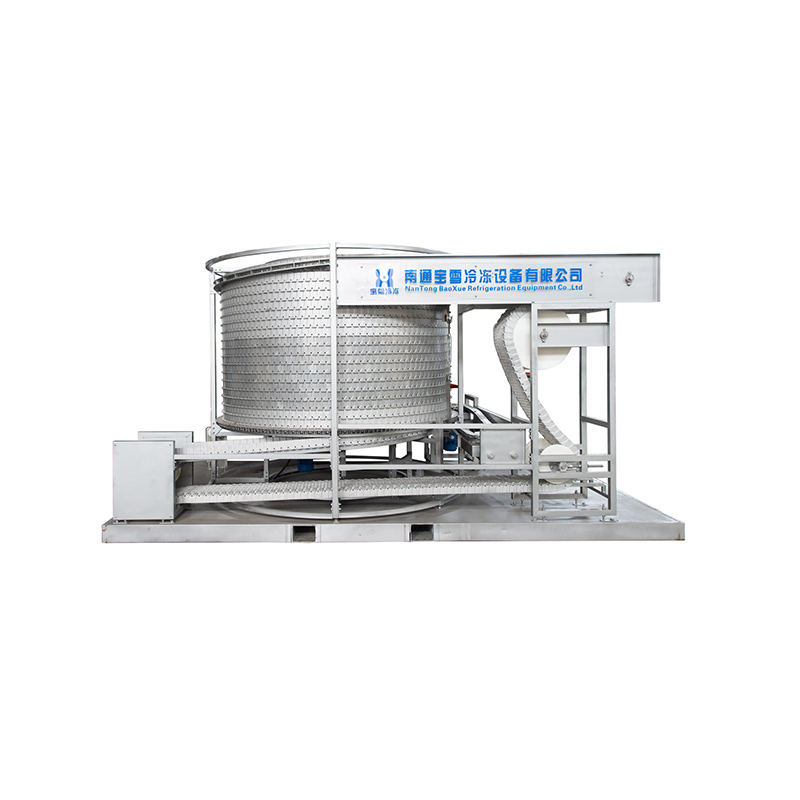

Self-stacking Spiral Freezer for Seafood, Fish, Poultry, Meat

Product Description

The self-stacking spiral freezer uses self-stacking belt chain driven system and vertical air flow. The food can be frozen in a shorter time in better quality. The self-stacking spiral Freezer Meats the highest hygiene and energy efficiency standard. The self-stacking belt is driven by chain system operates completely on rolling balls. The resistance and noise caused by running chain is reduced. So smaller Motors can drive the system. The belt is not in tension in run. The belt is less likely to be stretched and deformed. Self-stacking belt stacks on the top of each other’s side links. This self-stacking feature eliminates the rail supporting the belt. The unique belt design contains the product in a self-contained freezing zone for gentle and uniform handling and superior hygiene. The vertical airflow of high velocity touches the product through all stacks, providing even quick efficient freezing result. The special holes on the side links also introduce cold air into product zone and create turbulence. This provides uniform product temperature across the belt and increases the heat exchanging efficiency. The centrifugal fans on the top of the coil suck the cold air from the coil and push the high velocity air down through all belt tiers.

The ADF stands for automatic defrosting. The ADF system blows pulses of pressurized sir of high velocity repeatedly over the evaporator fins to remove the frost while the products continue to run in the freezer. The heat transfer efficiency is significantly improved. The air defrosting can extend production runtime by 150 to 200 by eliminating frost build up on the evaporator.

The self-stacking freezer is ideal for quick freezing of fried food, ready meal and pastry. The design eliminates the belt supporting rails and cages. It is hygienic and easy to clean. The self-stacking freezer provided CIP system. CIP is the full mode. It cleans product zone, coil, enclosure and structure. The system has multiple cleaning programs for customer to choose, including lathering, rinsing, disinfectant spraying and belt drying. The fully welded and sloped floor and ensures fast and complete drainage. The BX freezing will continue to provide market with innovative freezing equipment product and service.

Technical Specifications

|

Model |

Production capacity(kg/h) |

Refrigeration capacity(kw) |

Motor power(kw) |

Refrigerant |

Overall dimension L (mm) |

|

SSF-500 |

500 |

80 |

23.5 |

R404A/R717 |

9800×.300×2500 |

|

SSF-750 |

750 |

125 |

30 |

R404A/R717 |

10200×3700×2500 |

|

SSF-1000 |

1000 |

160 |

32 |

R404A/R717 |

11800×4300×2000 |

|

SSF-1500 |

1500 |

230 |

38 |

R404A/R717 |

11800×4300×3500 |

|

SSF-2000 |

2000 |

310 |

45 |

R404A/R717 |

13000×5000×3500 |

|

SSF-2500 |

2500 |

370 |

52 |

R404A/R717 |

13600×5000×3500 |

|

SSF-3000 |

3000 |

450 |

56 |

R404A/R717 |

13600×5000×3700 |

For more models and customizations of the spiral freezer, please contact the sales manager.

Application

It is widely used in freezing fried food, ready meal and pastry.

Exhibition

What We Can Do for Our Customers

1. Customized Solutions

Customize the most suitable equipment according to the venue and frozen products.

Conveyor belts, floors, housing type options, etc. meet production requirements.

The optional CIP system and ADF system can extend the run time from daily to 14 days.

2. High output with energy saving and environmental protection

The air flow and temperature distribution are uniform through reasonable structural design to achieve the best heat transfer and minimum product dehydration. High performance unaffected by product load changes.

3. Low total cost

Optimize evaporation temperature to reduce energy consumption. Simple drive system, non-proprietary components, reliable structure and low maintenance cost.